An inline homogenizer is a high-shear mixing device used to emulsify, blend, and break down particles in liquid-liquid or liquid-solid mixtures. It is designed for continuous processing, making it ideal for high-volume production in pharmaceutical, cosmetic, chemical, dairy, and food industries.

Working Principle

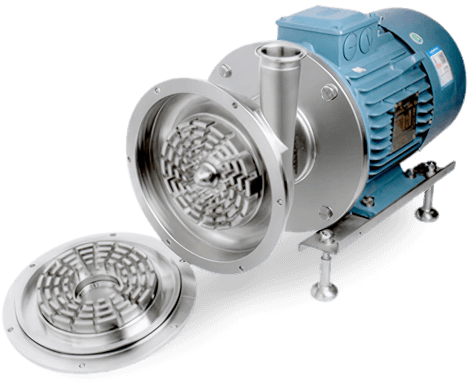

The inline homogenizer uses a rotor-stator mechanism to apply intense mechanical shear. As the material passes through the homogenizing chamber, it is subjected to high-speed rotation (up to 3000 RPM), creating turbulence, cavitation, and shear that break down particles and form stable emulsions or dispersions.

Applications

Advantages:

Features:

Rotor-Stator Assembly:

Precision-engineered for high-shear mixing and fine emulsification.

Motor & Shaft:

High-speed motor with sealed bearings for continuous operation.

Mechanical Seal:

Leak-proof seal suitable for high-pressure and hygienic environments.

Inlet & Outlet Ports:

Designed for continuous flow of materials through the homogenizing chamber.

Base Frame:

Skid-mounted compact frame with vibration-dampening support.

Control Panel:

Includes start/stop buttons, speed control, and overload protection.